What is an Automatic Blister Packing Machine and How Does It Work

The automatic blister packing machine has revolutionized the packaging industry by offering a streamlined and efficient solution for packaging various products, particularly in the pharmaceutical and consumer goods sectors. This advanced piece of equipment automates the process of creating blister packs, which are widely used to package tablets, capsules, and other items securely. In this guide, we will explore what an automatic blister packing machine is, its key components, and how it operates to enhance productivity and maintain product integrity. Understanding the functionality and advantages of this machinery can help businesses optimize their packaging processes, reduce labor costs, and ensure consistent quality in their products. Join us as we delve into the intricacies of automatic blister packing machines and discover how they can transform packaging operations.

Understanding the Basics of Automatic Blister Packing Machines

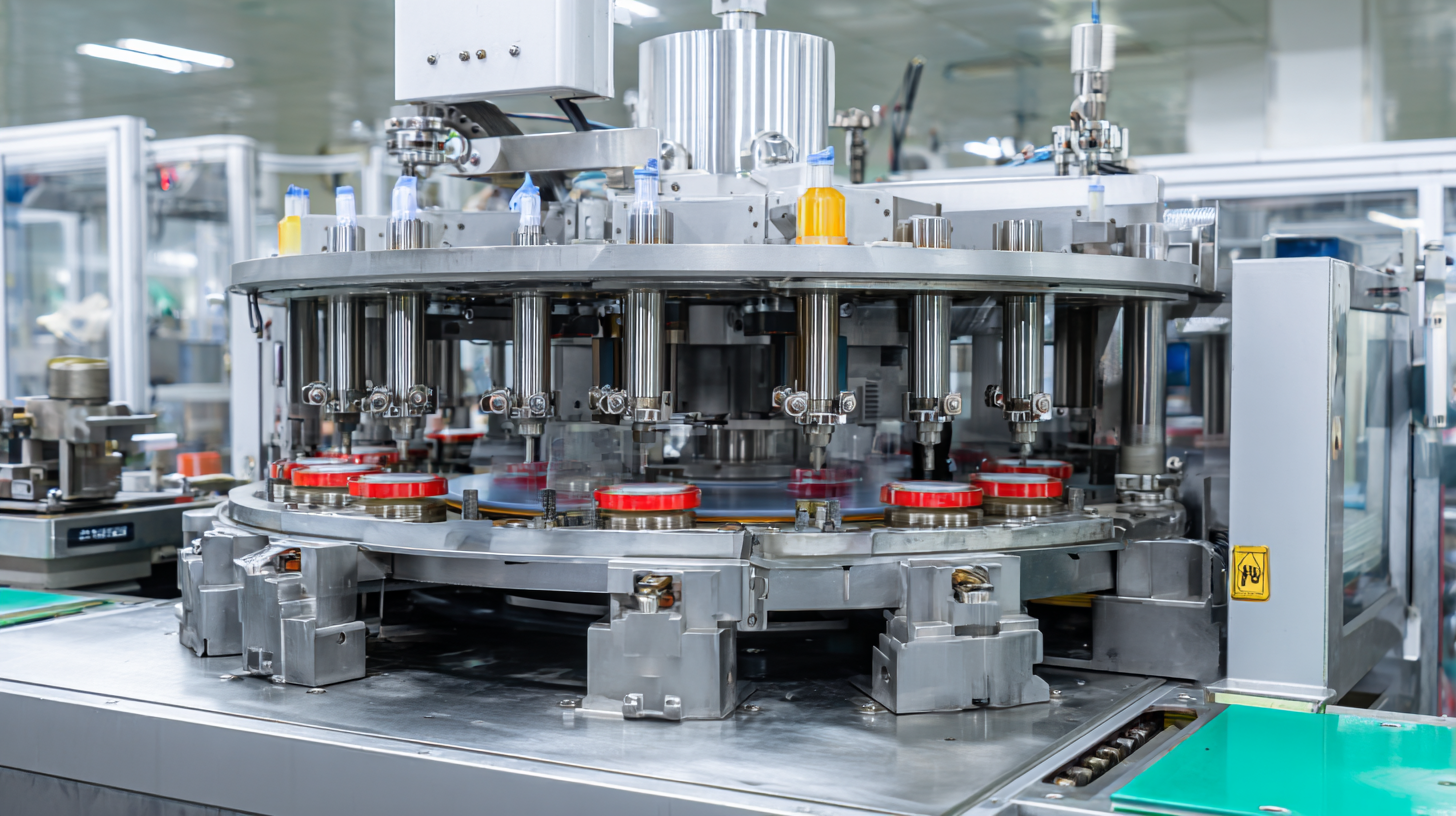

An automatic blister packing machine is an essential piece of equipment in the pharmaceutical and packaging industries, designed to package products in a protective blister format. Understanding the basics of these machines reveals their significance in ensuring product safety and extending shelf life. Typically, these machines operate by forming a cavity or pocket from a thermoplastic sheet, which is then filled with the product, such as tablets or capsules, and sealed with a backing material. This process minimizes the risk of contamination and damage, providing a reliable method of packaging.

The functioning of an automatic blister packing machine involves several key components, including feeders for product insertion, heating sections for plastic forming, and sealing units for final packaging. Automation in these machines allows for high-speed production and reduces labor costs, enhancing efficiency in manufacturing processes. Additionally, many modern machines are equipped with advanced control systems and sensors, ensuring precise operation and quality control throughout the packing cycle. By understanding these fundamentals, industries can better appreciate the role of automatic blister packing machines in enhancing product reliability and consumer safety.

Key Components That Make Up Automatic Blister Packing Machines

Automatic blister packing machines are integral to the packaging industry, designed to efficiently encase products in blister compartments. These machines typically consist of several key components, including feeders, formers, temperature control systems, and sealing units. Each of these components works together to streamline the packing process, ensuring speed and accuracy. For instance, the feeder system aligns products precisely as they move into the blister, while temperature control guarantees that the sealing process is performed optimally, preventing leaks and product damage.

The market for blister packing machines is experiencing substantial growth, driven by advancements in technology and increasing demand for efficient packaging solutions. According to a recent industry analysis, the global market for automatic blister packing machines is projected to grow significantly, with a notable shift towards automation in response to labor shortages. The integration of AI-powered motion control and robotics has revolutionized the way packaging operations are executed, leading to improvements in speed and sustainability. Reports indicate that companies implementing these automated solutions are achieving up to 30% reductions in operational costs, positioning themselves favorably in a competitive landscape.

How Automatic Blister Packing Machines Operate in Different Industries

Automatic blister packing machines have become crucial in various industries, particularly in pharmaceuticals, food packaging, and cosmetics. In the pharmaceutical sector alone, the global blister packaging market was valued at approximately $17.1 billion in 2020 and is projected to reach $28 billion by 2026, growing at a CAGR of 8.5%. These machines offer a reliable solution for ensuring product safety and longevity, as they effectively protect sensitive items from environmental factors like moisture and air.

In the food industry, automatic blister packing machines are increasingly used to extend shelf life and enhance product visibility. The global demand for food packaging solutions has surged, with a report by Grand View Research indicating the food packaging market is expected to reach $500 billion by 2026. Blister packs provide an integrated means to display products attractively while maintaining freshness, which plays a critical role in consumer purchasing decisions. Furthermore, cosmetic brands are adopting these machines to meet the rising consumer demand for convenience and product integrity, showcasing their formulations in tamper-proof and visually appealing packs.

Overall, automatic blister packing machines are indispensable across these sectors, automating processes that enhance efficiency, reduce waste, and ensure compliance with stringent health regulations. Their versatility and effectiveness make them a key innovation in modern packaging solutions.

Usage of Automatic Blister Packing Machines in Different Industries

This chart illustrates the percentage of automatic blister packing machine usage across various industries, highlighting their importance in the pharmaceutical, food, cosmetic, and electronics sectors.

Advantages of Using Automatic Blister Packing Machines for Packaging

Automatic blister packing machines offer significant advantages in the pharmaceutical packaging industry. These machines streamline the packaging process, ensuring efficiency and consistency while maintaining high standards for product safety and integrity. The global pharmaceutical blister packaging market is poised for substantial growth, projected to rise from $21.75 billion in 2024 to approximately $45.46 billion by 2034. This growth signifies that more companies are recognizing the importance of automated solutions for reducing production costs and enhancing productivity.

Automatic blister packing machines offer significant advantages in the pharmaceutical packaging industry. These machines streamline the packaging process, ensuring efficiency and consistency while maintaining high standards for product safety and integrity. The global pharmaceutical blister packaging market is poised for substantial growth, projected to rise from $21.75 billion in 2024 to approximately $45.46 billion by 2034. This growth signifies that more companies are recognizing the importance of automated solutions for reducing production costs and enhancing productivity.

The benefits of using automatic blister packing machines include increased speed and accuracy in packaging operations. This is particularly important in a market where adherence to strict regulatory standards is crucial. For instance, automated systems can minimize human error and optimize the use of materials, ensuring a secure seal that protects the integrity of pharmaceuticals. The use of advanced technologies in these machines, such as servo systems, not only enhances performance but also supports flexible packaging options.

Tips: When considering automatic blister packing solutions, evaluate the scalability of the machine to meet future production increases. Additionally, prioritize machines equipped with the latest technologies to enhance operational efficiency and compliance with industry regulations.

Maintenance Tips for Optimal Performance of Blister Packing Machines

Maintaining blister packing machines is essential for ensuring optimal performance and longevity in production lines. Regular maintenance helps prevent costly downtime and ensures that the machine operates efficiently. According to industry reports, approximately 70% of machine failures are due to lack of proper maintenance, emphasizing the need for routine checks. Operators should schedule daily inspections of key components such as sealing plates, temperature sensors, and cutting blades. Keeping these parts clean and properly calibrated can significantly enhance the efficacy of the packaging process.

Moreover, lubrication is crucial for the moving parts of blister packing machines. Regular application of the recommended lubricants can reduce friction and prevent wear and tear, extending the lifespan of these machines. Data from equipment manufacturers indicate that well-lubricated machines can operate up to 20% more efficiently, which can lead to increased throughput. Additionally, operators should keep software up to date and conduct periodic training sessions for staff to ensure they are familiar with the latest operational protocols. By implementing these maintenance tips, manufacturers can achieve not only optimal machine performance but also significant cost savings in the long run.

What is an Automatic Blister Packing Machine and How Does It Work - Maintenance Tips for Optimal Performance of Blister Packing Machines

| Feature | Description | Importance |

|---|---|---|

| Machine Type | Automatic Blister Packing Machine | High efficiency in packaging. |

| Primary Function | To package pharmaceuticals, food, and other products in blister packs. | Ensures product protection and exact dosage. |

| Operation Principle | Utilizes heat and pressure to form blister packs from plastic materials. | Improves speed and reduces handling errors. |

| Maintenance Tip | Regularly lubricate moving parts to minimize wear. | Extends the lifespan of the machine. |

| Common Issue | Incorrect blister sealing. | Can lead to product contamination and loss. |

| Cleaning Frequency | After every production run. | Prevents cross-contamination。 |

Related Posts

-

Exploring Innovative Alternatives to the Traditional Blister Packing Machine

-

Essential Guide to Choosing the Right Stock Clamshell Packaging for Global Markets

-

How to Choose the Right Clear Clamshell Packaging for Your Products

-

What is the Importance of Blister Packaging Machine in Modern Manufacturing

-

How to Select the Right Blister Card Packaging for Your Product

-

How to Optimize Your Blister Card Packaging for Enhanced Product Visibility and Sales Performance