Exploring the Benefits of Using an Automatic Blister Packing Machine in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the adoption of technology plays a pivotal role in enhancing efficiency and productivity. One key advancement is the utilization of an automatic blister packing machine, which offers significant advantages over traditional packing methods. According to a recent report by MarketsandMarkets, the global blister packaging market is projected to reach USD 39.47 billion by 2025, driven by the growing demand for protective and user-friendly packaging solutions across various industries. An automatic blister packing machine not only streamlines the packaging process but also minimizes waste and reduces labor costs, leading to improved operational efficiency. As manufacturers strive to meet increasing consumer expectations and stringent regulatory standards, integrating such innovations becomes essential for maintaining competitiveness in the market. This article explores the myriad benefits of utilizing an automatic blister packing machine and its impact on modern manufacturing practices.

In the rapidly evolving landscape of modern manufacturing, the adoption of technology plays a pivotal role in enhancing efficiency and productivity. One key advancement is the utilization of an automatic blister packing machine, which offers significant advantages over traditional packing methods. According to a recent report by MarketsandMarkets, the global blister packaging market is projected to reach USD 39.47 billion by 2025, driven by the growing demand for protective and user-friendly packaging solutions across various industries. An automatic blister packing machine not only streamlines the packaging process but also minimizes waste and reduces labor costs, leading to improved operational efficiency. As manufacturers strive to meet increasing consumer expectations and stringent regulatory standards, integrating such innovations becomes essential for maintaining competitiveness in the market. This article explores the myriad benefits of utilizing an automatic blister packing machine and its impact on modern manufacturing practices.

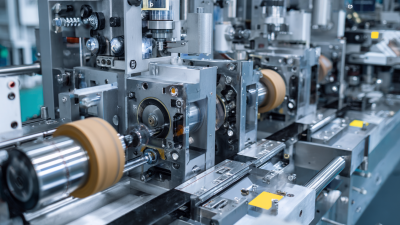

The Role of Automatic Blister Packing Machines in Enhancing Production Efficiency

In modern manufacturing, efficiency is paramount, and automatic blister packing machines play a critical role in streamlining production processes. According to a report by Smithers Pira, the global market for blister packaging is expected to grow at a CAGR of 6.4% from 2020 to 2025. This growth underscores the increasing reliance of manufacturers on automated solutions to enhance output while maintaining product integrity. Automatic blister packing machines can achieve speeds of up to 300 packs per minute, significantly reducing labor costs and production time compared to manual packing methods.

Tips: When considering the implementation of an automatic blister packing machine, evaluate your production volume and product type. This evaluation will ensure you select a machine that aligns with your operational needs, maximizing both efficiency and ROI.

Furthermore, automatic blister packing machines provide added benefits such as improved accuracy and reduced waste. A study by the Association for Packaging and Processing Technologies revealed that automated systems can decrease product defects by up to 30%, leading to higher customer satisfaction rates. This level of precision not only elevates the overall quality of the packaged product but also enhances the manufacturer's reputation in the competitive marketplace.

Tips: Regular maintenance and timely upgrades of your blister packing machine can prevent downtime and keep your production line running smoothly, ensuring continued efficiency over time.

Benefits of Using an Automatic Blister Packing Machine in Modern Manufacturing

Key Cost Savings Achieved Through Automation in Packaging Processes

The benefits of integrating automatic blister packing machines into modern manufacturing processes focus significantly on the key cost savings achieved through automation in packaging. With the rise of smart factories and automated systems, companies can streamline operations, minimize labor costs, and reduce material waste. This shift not only enhances productivity but also allows manufacturers to allocate resources more efficiently, thereby boosting overall profitability.

Recent advancements in technology have highlighted the importance of automation in the packaging sector. For instance, companies are adopting automated packing solutions to improve precision and speed during production. These machines reduce the reliance on manual labor, which is associated with higher error rates and operational costs. Furthermore, the implementation of sensors and smart technologies ensures that maintenance is carried out according to real-time needs, further reducing downtime and enhancing the reliability of packaging processes. As more manufacturers transition to automated systems, the packaging industry is poised for significant growth and improvement.

Exploring the Benefits of Using an Automatic Blister Packing Machine in Modern Manufacturing - Key Cost Savings Achieved Through Automation in Packaging Processes

| Dimension | Before Automation | After Automation | Cost Savings (%) |

|---|---|---|---|

| Labor Costs | $50,000 | $30,000 | 40% |

| Material Waste | $15,000 | $5,000 | 66.67% |

| Production Time | 120 hours/month | 75 hours/month | 37.5% |

| Energy Costs | $8,000 | $6,000 | 25% |

| Total Cost | $73,000 | $46,000 | 37.04% |

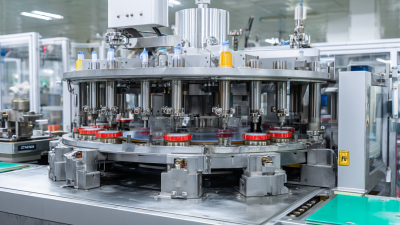

Impact of Automatic Blister Packing on Reducing Product Damage Rates

The integration of automatic blister packing machines in modern manufacturing processes significantly enhances product protection, particularly in the pharmaceutical and food industries. This technology helps streamline packaging operations, reducing human error and improving the overall efficiency of production lines. By utilizing precise sealing mechanisms, these automatic machines minimize the risk of product damage, which can arise from improper handling or environmental factors. As a result, products are better preserved, leading to decreased wastage and increased consumer trust.

Moreover, the impact of automatic blister packing extends beyond reducing damage rates; it also addresses the growing concerns surrounding packaging integrity. With an anticipated growth in the pharmaceutical blister packaging market, expected to reach approximately USD 45.46 billion by 2034, the demand for robust packaging solutions that ensure the safety and efficacy of medications is ever-increasing. Automatic blister packing machines play a vital role in maintaining seal integrity, thus protecting contents from moisture, contamination, and other external threats. This evolution in packaging technology not only supports manufacturers in achieving compliance with stringent industry standards but also contributes to a more sustainable approach by minimizing product loss and enhancing consumer safety.

Technological Advancements in Blister Packing and Their Industry Implications

The advancement of technology in blister packing has significantly transformed the manufacturing landscape. According to a report by Allied Market Research, the global blister packaging market is projected to reach $31.6 billion by 2027, growing at a CAGR of 5.8% from 2020 to 2027. This growth can be attributed to the increasing demand for efficient packaging solutions that enhance product safety and extend shelf life.

Automatic blister packing machines are at the forefront of this evolution, providing manufacturers with the ability to streamline operations, reduce labor costs, and improve overall productivity.

Automatic blister packing machines are at the forefront of this evolution, providing manufacturers with the ability to streamline operations, reduce labor costs, and improve overall productivity.

Moreover, innovations such as smart technology integration in automatic blister packing machines are paving the way for greater efficiency and quality control. For instance, machines equipped with vision systems can detect packaging defects in real-time, ensuring that only products meeting rigorous standards reach consumers. A report from MarketsandMarkets highlights that the demand for automated packaging solutions is driven by the pharmaceutical and food sectors, which contribute significantly to the market. This trend is indicative of a broader industry shift towards automation, as companies seek to meet regulatory standards while accommodating the increasing complexities of modern supply chains.

Best Practices for Integrating Automatic Blister Packing Machines into Existing Manufacturing Lines

Integrating automatic blister packing machines into existing manufacturing lines offers significant advantages, but doing so requires careful planning and execution. First, manufacturers should assess their current workflows to identify potential bottlenecks and areas for improvement. Understanding the specific needs of the production process, including product dimensions and packaging requirements, will ensure a seamless transition. Collaboration with equipment suppliers can provide valuable insights into the customization options available, allowing for the machines to be tailored to fit existing setups.

Once the machines are acquired, training personnel becomes crucial for maximizing efficiency. Operators should be familiarized with the machine’s features and maintenance requirements. Implementing a robust training program helps mitigate errors and minimizes downtime, ensuring that the integration of the blister packing machine enhances productivity. Furthermore, regular feedback from employees can inform ongoing adjustments to optimize performance. By prioritizing these best practices, manufacturers can successfully incorporate automatic blister packing machines, resulting in streamlined operations and enhanced product quality.

Related Posts

-

How to Select the Right Blister Packing Machine for Your Production Needs

-

Exploring Innovative Alternatives to the Traditional Blister Packing Machine

-

7 Best Strategies to Optimize Your Blister Machine Investment

-

What is an Automatic Blister Packing Machine and How Does It Work

-

Understanding the Role of Blister Packaging Machines in Modern Manufacturing Processes

-

Exploring the Future of Plastic Blister Packaging: Innovations and Sustainability Trends Behind 2023's Market Growth