Exploring the Benefits of Vacuum Formed Trays in Modern Packaging Solutions

The packaging industry is undergoing a transformative phase, driven by the need for efficiency, sustainability, and consumer appeal. Among the innovative solutions gaining traction are vacuum formed trays, which have proven to be advantageous in various sectors, including food, pharmaceuticals, and electronics. According to a report by Smithers Pira, the global market for thermoformed packaging, which includes vacuum formed trays, is projected to reach $38.3 billion by 2024, reflecting a compound annual growth rate (CAGR) of 4.5%. These trays not only offer superior protection and shelf-life extension for products but also contribute significantly to reducing material waste. Their lightweight and customizable nature further align with the industry’s movement towards sustainable practices. As businesses seek to enhance their packaging efficiency while meeting consumer demands for eco-friendliness, vacuum formed trays emerge as a pivotal solution in modern packaging strategies.

The packaging industry is undergoing a transformative phase, driven by the need for efficiency, sustainability, and consumer appeal. Among the innovative solutions gaining traction are vacuum formed trays, which have proven to be advantageous in various sectors, including food, pharmaceuticals, and electronics. According to a report by Smithers Pira, the global market for thermoformed packaging, which includes vacuum formed trays, is projected to reach $38.3 billion by 2024, reflecting a compound annual growth rate (CAGR) of 4.5%. These trays not only offer superior protection and shelf-life extension for products but also contribute significantly to reducing material waste. Their lightweight and customizable nature further align with the industry’s movement towards sustainable practices. As businesses seek to enhance their packaging efficiency while meeting consumer demands for eco-friendliness, vacuum formed trays emerge as a pivotal solution in modern packaging strategies.

Overview of Vacuum Formed Trays and Their Applications in Packaging

Vacuum formed trays have emerged as a crucial component in modern packaging solutions due to their versatility and efficiency. These trays are created by heating a thermoplastic sheet until it becomes pliable, then forming it over a mold to achieve the desired shape. This method allows for the production of intricate designs and precise dimensions, making vacuum formed trays ideal for various applications such as food packaging, electronic components, and medical devices. Their lightweight nature combined with durability offers significant advantages in reducing shipping costs while maintaining product safety.

Tips for Using Vacuum Formed Trays:

When implementing vacuum formed trays in your packaging strategy, consider using high-quality materials that provide excellent protection against environmental factors. Additionally, utilizing custom molds can enhance product presentation and branding. It’s also beneficial to assess the compatibility of trays with your production line to streamline operations and ensure efficiency.

The adaptability of vacuum formed trays allows businesses to cater to different market demands while optimizing their packaging processes. As industries continue to evolve, these trays offer innovative solutions that meet the sustainability goals of reducing waste and enhancing recyclability, further solidifying their place in modern packaging strategies.

Key Advantages of Vacuum Formed Trays in Product Protection and Preservation

Vacuum formed trays have rapidly gained popularity in modern packaging solutions, primarily due to their exceptional capacity for product protection and preservation. These trays are crafted from thermoplastic materials that are precisely molded to fit the contours of various products. This snug fit not only helps to reduce damage during shipping and handling, but it also minimizes product movement within the package, ensuring that items remain secure and intact. As a result, businesses can mitigate the risk of product loss or damage, leading to lower costs associated with returns and replacements.

In addition to protection, vacuum formed trays also offer significant advantages for product preservation. The sealed design forms an airtight barrier that helps to keep moisture, dust, and contaminants at bay, extending the shelf life of perishable items. This is particularly beneficial for food packaging, where freshness is crucial. Moreover, the ability to customize these trays for specific products allows for improved branding opportunities, helping companies stand out in a competitive market while ensuring that their products maintain their quality and appeal until they reach the consumer.

Environmental Impact Considerations of Vacuum Formed Packaging Solutions

Vacuum formed trays have emerged as a leading choice in modern packaging solutions, not only for their efficiency but also for their potential environmental benefits. According to a report by Smithers Pira, the global market for vacuum formed packaging is projected to reach $30 billion by 2025, signaling a significant shift towards sustainable practices. One of the primary environmental advantages of vacuum formed trays is their lightweight nature, which reduces the carbon footprint during transportation. With transportation accounting for a considerable percentage of packaging-related emissions, lighter packages mean lower fuel consumption and fewer greenhouse gas emissions.

Moreover, the material used in vacuum formed trays is often recyclable and can be produced from recycled plastics. A study from the Ellen MacArthur Foundation highlights that using recycled materials can reduce the environmental impact of packaging by up to 60% compared to virgin materials. Additionally, the production process of vacuum formed trays typically consumes less energy than traditional packaging methods. By minimizing waste and maximizing recyclability, vacuum formed trays represent a compelling option for companies aiming to meet sustainability targets while still delivering effective packaging solutions.

Innovative Designs and Customization Options for Vacuum Formed Trays

Vacuum formed trays have revolutionized modern packaging solutions, particularly in the realm of innovative designs and customization options. According to a recent report by Smithers Pira, the global market for vacuum-formed packaging is projected to reach $30 billion by 2025, highlighting the increasing demand for tailored packaging solutions across various industries. The ability to create intricate designs that cater specifically to product requirements enables manufacturers to enhance consumer appeal and optimize the use of space.

Customization options available with vacuum formed trays are vast, allowing companies to design packaging that not only protects the product but also showcases it effectively. For example, businesses can incorporate branding elements directly into the tray design, using colors and textures that align with their overall marketing strategy. Moreover, advanced technology allows for precise cuts and shapes, ensuring a snug fit for a wide array of products, from electronics to food items. This adaptability not only improves shelf presence but also aids in reducing material waste, as custom sizes can minimize excess packaging. As sustainability continues to be a priority, the efficient use of materials provided by vacuum forming processes aligns seamlessly with these industry trends.

Benefits of Vacuum Formed Trays in Modern Packaging Solutions

Case Studies: Successful Implementation of Vacuum Formed Trays in Various Industries

Vacuum formed trays have emerged as a pivotal element in modern packaging solutions, offering numerous benefits across various industries. Their lightweight and durable nature make them ideal for protecting delicate items during transportation and storage. According to a recent report by the Plastics Industry Association, the vacuum forming process results in a reduction of material usage by up to 30%, leading not only to cost savings but also to a more sustainable packaging option. This efficiency in resource utilization highlights how vacuum formed trays are increasingly becoming the go-to choice for manufacturers aiming to minimize their environmental impact.

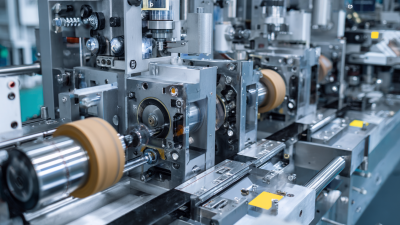

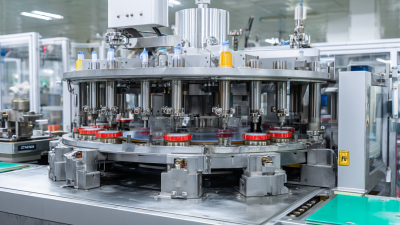

In industries such as healthcare and food service, successful case studies have demonstrated the versatility of vacuum formed trays. For instance, in the medical sector, companies have adopted these trays for secure and sterile packaging of surgical instruments, ensuring safety and efficiency. In the food industry, vacuum formed trays are used extensively for fresh produce and ready-to-eat meals, as their design effectively extends shelf life while maintaining food quality. Furthermore, with the integration of intelligent robotics in various production processes, the precision offered by robotics complements the efficiency of vacuum formed trays, enabling manufacturers to streamline operations and meet rising consumer demands for both accessibility and innovation.

Related Posts

-

How to Select the Right Blister Card Packaging for Your Product

-

7 Best Strategies to Optimize Your Blister Machine Investment

-

How to Optimize Your Blister Card Packaging for Enhanced Product Visibility and Sales Performance

-

Essential Checklist for Choosing the Right Plastic Clamshells for Your Products

-

What is an Automatic Blister Packing Machine and How Does It Work

-

7 Tips for Maximizing Efficiency with Thermoform Packaging