7 Best Strategies to Optimize Your Blister Machine Investment

In the competitive landscape of the pharmaceutical and packaging industries, optimizing investments in technology such as a blister machine is crucial for maximizing efficiency and output. According to a recent report by Allied Market Research, the global blister packaging market is projected to reach $31.83 billion by 2027, growing at a CAGR of 6.4% from 2020. This growth underscores the increasing reliance on blister machines for secure, tamper-resistant packaging solutions that enhance product visibility and shelf life. As companies look to capitalize on this trend, investing in advanced blister machines becomes not just a matter of necessity but a strategic imperative. However, merely acquiring state-of-the-art equipment is not enough; organizations must implement effective strategies to optimize their blister machine investment. In this blog, we explore the seven best strategies that can help businesses achieve greater operational efficiency and higher returns on investment.

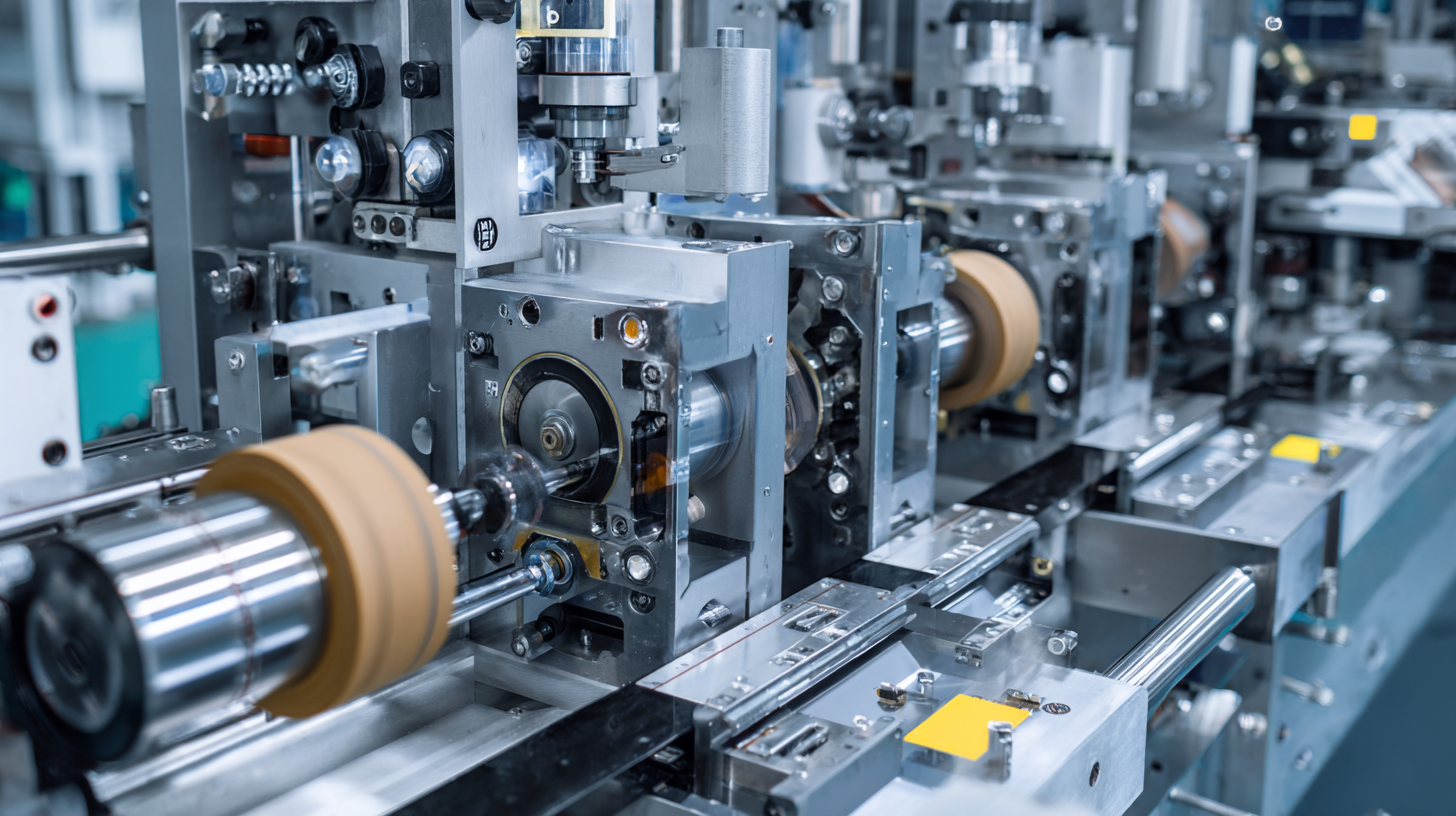

Identifying the Right Blister Machine for Your Production Needs

When considering a blister machine investment, identifying the right model for your production needs is paramount. Each production line is unique, and selecting a machine that aligns with your specific requirements can significantly enhance efficiency and output. Start by evaluating the types of products you intend to package. Are they pharmaceuticals, food items, or consumer goods? Each category may require different specifications in terms of material compatibility and sealing techniques.

Tip: Assess your production volume and frequency. If your operation is high-volume, invest in a machine with faster cycle times and automated features to keep up with demand. On the other hand, for smaller batches or specialized products, a semi-automatic machine may suffice, offering flexibility without the need for heavy investment.

Another crucial factor to consider is the ease of maintenance and operator training. A user-friendly interface can reduce downtime, and having a machine that is easy to maintain ensures that production runs smoothly. Additionally, ensure that adequate training resources are available for your team to optimize performance and minimize errors during the production process.

Tip: Research the availability of spare parts and support services for the blister machine you select. A reliable supplier can make all the difference in minimizing operational hiccups and ensuring long-term productivity.

Maximizing Efficiency: Best Practices for Operating Your Blister Machine

Maximizing the efficiency of your blister machine involves implementing several best practices that streamline operations and reduce waste. First and foremost, regular maintenance is crucial. Scheduling routine checks and timely repairs can prevent unexpected downtimes and costly fixes. Additionally, operators should be thoroughly trained on the machine’s functionality, ensuring they can quickly troubleshoot minor issues and optimize settings for different product runs. A well-trained team not only enhances productivity but also fosters a culture of safety and awareness on the production floor.

Moreover, leveraging technology can significantly boost your machine's efficiency. Utilizing software that integrates with your blister machine allows for real-time monitoring and data analysis. This technology helps identify bottlenecks in production and provides insight into operational metrics, empowering managers to make data-driven decisions. Additionally, consider optimizing the materials used, as high-quality films and foils can improve sealing integrity and enhance the final product's appearance, leading to fewer rejections and maximizing yield. By focusing on these best practices, you can ensure your blister machine operates at peak performance, contributing positively to your overall investment strategy.

7 Best Strategies to Optimize Your Blister Machine Investment

| Strategy | Description | Expected Benefits |

|---|---|---|

| Regular Maintenance | Schedule routine checks and servicing. | Reduced downtime and extended machine life. |

| Operator Training | Invest in comprehensive training programs for operators. | Increased productivity and lower error rates. |

| Material Selection | Choose high-quality materials for packaging. | Enhanced product protection and reduced waste. |

| Process Optimization | Analyze and improve workflow processes. | Faster production times and lower costs. |

| Utilize Technology | Implement automation and monitoring systems. | Improved accuracy and real-time insights. |

| Regular Performance Reviews | Conduct frequent assessments of machine performance. | Identification of improvement areas and enhanced output. |

| Collaboration with Suppliers | Work closely with material suppliers. | Better material quality and innovative solutions. |

Regular Maintenance Tips to Extend the Life of Your Blister Machine

Regular maintenance is essential for extending the life of your blister machine, ensuring that it runs efficiently and produces high-quality packaging. Manufacturers of blister packaging equipment have been focusing on advancements that enhance flexibility and integrate seamlessly with other production line components. This means that regular check-ups should include assessing how well your machine integrates with upstream and downstream processes, to minimize downtime and maintain productivity.

One key maintenance tip is to regularly calibrate servo controls and check for any signs of wear and tear on compact parts. It's vital to create a maintenance schedule that addresses these aspects to prevent costly breakdowns. Keeping up with these practices will not only prolong the lifespan of your blister machine but also optimize your investment, allowing it to adapt to evolving packaging demands while maintaining high operational standards. By prioritizing maintenance, you can ensure that your equipment remains a reliable asset for your business operations.

Training Your Team: Enhancing Skills for Optimal Blister Machine Performance

Training your team is a fundamental aspect of optimizing your blister machine investment. According to a report by the Society of Plastics Engineers, companies that implement

structured training programs see an increase in production efficiency by up to

25%. This improvement stems from team members being better equipped to troubleshoot mechanical issues and optimize machine settings based on their product specifications. By enhancing their skills, operators can significantly reduce downtime and improve the overall lifecycle of machinery.

Moreover, investing in team training aligns with the industry's shift toward automation and robotics. The International Federation of Robotics states that 87% of manufacturers believe skilled personnel are crucial for successfully integrating advanced technologies. With a well-trained team, you can ensure that your blister machine operates at peak performance, maximizing throughput and minimizing waste.

Regular training sessions, workshops, and hands-on practice not only elevate technical skills but also foster a culture of innovation and continuous improvement, ultimately transforming your manufacturing capabilities.

Analyzing Production Data to Improve Blister Machine Output and Quality

Analyzing production data is crucial for enhancing the output and quality of blister machines in the pharmaceutical packaging industry. According to a recent report by Grand View Research, the global blister packaging market is projected to reach $37.4 billion by 2025, highlighting the increasing importance of efficient packaging solutions. By systematically collecting and analyzing production data, manufacturers can identify bottlenecks in the blister formation process, optimize material usage, and reduce waste. For instance, leveraging software tools that monitor machine performance in real-time can lead to a 15-20% increase in productivity through timely adjustments and preventive maintenance.

Furthermore, quality control metrics derived from production data can significantly impact the final product integrity. A study by Packaging Strategies reports that up to 60% of pharmaceutical recalls are linked to packaging issues. By utilizing statistical process control (SPC) methods, companies can detect anomalies in blister seal quality or film consistency early on, thereby increasing compliance with stringent regulatory standards. Implementing data analytics not only enhances production efficiency but also ensures that the final product meets the high standards expected in the pharmaceutical sector, ultimately leading to a stronger return on investment for blister machine users.

Related Posts

-

Exploring Innovative Alternatives to the Traditional Blister Packing Machine

-

What is the Importance of Blister Packaging Machine in Modern Manufacturing

-

Essential Checklist for Choosing the Right Plastic Clamshells for Your Products

-

5 Essential Tips for Choosing the Best Blister Packaging Materials

-

Addressing Challenges in Clam Packaging for Optimal Product Preservation

-

Essential Guide to Choosing the Right Stock Clamshell Packaging for Global Markets