Understanding the Role of Blister Packaging Machines in Modern Manufacturing Processes

In today's fast-paced manufacturing landscape, the efficiency and reliability of packaging solutions play a crucial role in product delivery and consumer satisfaction. One such solution that has gained immense popularity is the blister packaging machine. These machines not only enhance the protection of products but also streamline production processes by significantly reducing manual labor and minimizing errors. As industries ranging from pharmaceuticals to consumer goods increasingly recognize the benefits of automated packaging, understanding how to effectively implement and operate blister packaging machines becomes essential. This guide will delve into the intricacies of blister packaging machines, discussing best practices, key considerations for selection, and tips for maximizing their efficiency in modern manufacturing operations. Whether you are a seasoned professional in the packaging industry or a newcomer looking to enhance your packaging capabilities, this comprehensive overview aims to provide valuable insights into utilizing blister packaging machines to optimize your manufacturing processes.

The Importance of Blister Packaging Machines in Enhancing Production Efficiency

Blister packaging machines play a crucial role in modern manufacturing, particularly in sectors such as pharmaceuticals, food, and electronics. According to a report by Research and Markets, the global blister packaging market is expected to reach approximately $32 billion by 2026, growing at a CAGR of 6.5%. This rapid growth underscores the increasing importance of blister packaging in enhancing production efficiency. These machines not only streamline the packaging process but also ensure the protection and integrity of products, which is vital in maintaining quality and reducing waste.

The efficiency brought about by blister packaging machines can significantly impact production timelines and costs. In a study by Mordor Intelligence, it was found that the introduction of automated blister packaging can enhance the speed of packaging lines by up to 25%, allowing manufacturers to meet growing consumer demand with fewer resources. Furthermore, advanced blister packaging solutions can reduce the incidence of contamination and product damage, which are critical factors that can affect the bottom line. By investing in modern blister packaging technology, manufacturers are not only improving their operational efficiency but also ensuring compliance with stringent regulatory standards in various industries.

Analyzing Cost-Saving Benefits of Blister Packaging in the Manufacturing Sector

Blister packaging has become a vital component in modern manufacturing processes, particularly due to its ability to significantly reduce costs. By providing a protective seal for products, blister packaging minimizes the risk of damage during shipping and handling, thus decreasing the rate of returns and wastage. This not only leads to lower manufacturing costs but also enhances customer satisfaction by ensuring that products arrive in pristine condition.

Blister packaging has become a vital component in modern manufacturing processes, particularly due to its ability to significantly reduce costs. By providing a protective seal for products, blister packaging minimizes the risk of damage during shipping and handling, thus decreasing the rate of returns and wastage. This not only leads to lower manufacturing costs but also enhances customer satisfaction by ensuring that products arrive in pristine condition.

Moreover, the efficiency of blister packaging machines plays a crucial role in streamlining production lines. These machines automate the packaging process, resulting in faster production rates and reduced labor costs. They also facilitate precise dosing of products, ensuring that the right amount is packaged every time, which optimizes inventory management. The ability to customize blister packs for various products adds value, allowing manufacturers to cater to diverse consumer preferences while maintaining cost-effectiveness. Overall, the integration of blister packaging not only supports operational efficiency but also contributes to substantial long-term savings in the manufacturing sector.

Impact of Blister Packaging on Product Shelf Life and Consumer Safety

Blister packaging has emerged as a pivotal aspect of the modern manufacturing landscape, especially in the pharmaceutical and consumer goods sectors. According to a report by Smithers Pira, the blister packaging market is expected to reach a value of $38.8 billion by 2024, reflecting its increasing importance in maintaining product integrity. One of the primary benefits of blister packaging is its impact on extending product shelf life. The airtight seals of blister packs protect contents from external factors such as moisture, light, and oxygen, which are critical enemies of pharmaceutical efficacy. For instance, medications that are sensitive to humidity can lose their potency rapidly if not adequately protected.

Furthermore, blister packaging significantly enhances consumer safety. A study by the National Institute for Pharmaceutical Technology and Education highlighted that improperly stored drugs can lead to a rise in adverse drug reactions, resulting in nearly 1.3 million hospitalizations annually in the United States alone. Blister packaging not only provides tamper evidence but also facilitates dose control, helping consumers adhere to prescribed dosages. As the industry continues to evolve, the role of blister packaging machines will likely expand, ensuring that products remain safe and effective for their intended use.

Understanding the Role of Blister Packaging Machines in Modern Manufacturing Processes - Impact of Blister Packaging on Product Shelf Life and Consumer Safety

| Dimension | Data |

|---|---|

| Average Shelf Life Extension | 20-30% |

| Reduction in Product Waste | 15-25% |

| Increase in Consumer Safety | Up to 35% |

| Prevalence in Pharmaceutical Industry | 70% |

| Common Materials Used | PVC, PVDC, Aluminum Foil |

| Typical Packaging Speeds | 20-100 cycles/min |

| Average Machine Lifespan | 10-15 years |

Technological Advances in Blister Packaging Machines and Their Industry Implications

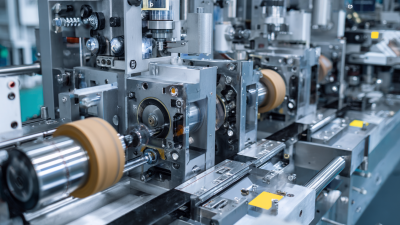

Technological advances in blister packaging machines have significantly transformed modern manufacturing processes across various industries. These sophisticated machines leverage cutting-edge technology, including automation and robotics, to enhance efficiency and precision in packaging. The integration of smart sensors and data analytics enables real-time monitoring and adjustments, leading to higher production rates and reduced material waste. These developments not only improve operational efficiency but also ensure consistent product quality, which is crucial in sectors such as pharmaceuticals and consumer goods.

Moreover, the implications of these technological improvements extend beyond manufacturing efficiency. The adoption of eco-friendly materials in blister packaging has gained momentum, prompted by both environmental concerns and regulatory requirements. This shift is leading companies to invest in advanced machinery that accommodates biodegradable films and recyclable materials. As a result, the packaging industry is moving toward more sustainable practices without compromising the protective qualities essential for product integrity. Through these innovations, blister packaging machines are shaping a more sustainable future while meeting the evolving demands of consumers and regulatory bodies alike.

Market Trends: Growth Projections for Blister Packaging Machines in Various Industries

The blister packaging machine market is witnessing substantial growth, paralleling trends observed across various sectors. According to a recent market research study, the global die cut lids market is projected to reach USD 1,840.5 million by 2034, with a remarkable CAGR of 7.3%. This surge reflects an increasing demand for efficient, supply-chain-friendly packaging solutions that enhance product shelf life and consumer convenience. Industries such as pharmaceuticals and consumer goods are driving this demand, highlighting the critical role blister packaging plays in modern manufacturing processes.

In the pharmaceutical sector, corrugated packaging is set to become a significant player with a projected market value of USD 16.13 billion by 2034. This growth suggests a shift in manufacturing strategies that prioritize sustainability and reduced environmental impact, a trend mirrored in the sealed wax packaging market, which is expected to expand significantly by 2035.

**Tips:** Investing in advanced blister packaging technologies can enhance manufacturing efficiency and boost product safety. Companies should also consider integrating sustainable materials into their packaging processes to align with growing consumer preferences for eco-friendly solutions. Keeping an eye on market trends and consumer demands will be crucial for sustained growth in this competitive landscape.

Related Posts

-

What is the Importance of Blister Packaging Machine in Modern Manufacturing

-

Exploring Innovative Alternatives to the Traditional Blister Packing Machine

-

7 Best Strategies to Optimize Your Blister Machine Investment

-

How to Select the Right Blister Packing Machine for Your Production Needs

-

Exploring Sustainable Solutions: The Advantages of Thermoformed Packaging Trays in Modern Manufacturing

-

Exploring Market Trends for Stock Clamshells at the 138th Canton Fair in 2025