How to Choose the Right Stock Blister Packaging for Your Products

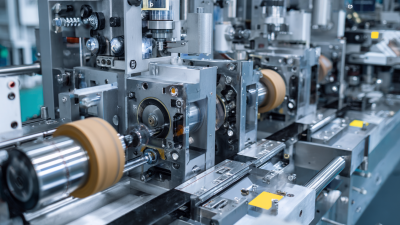

When it comes to packaging products, the choice of materials and design plays a pivotal role in not only ensuring product safety but also enhancing market appeal. One type of packaging that has gained significant traction in various industries is stock blister packaging. This versatile packing solution offers a durable and transparent way to display products while providing protection from environmental factors.

In this blog, we will explore the essential aspects of selecting the right stock blister packaging for your products. From understanding the different types available to recognizing the specific needs of your items, making informed choices can lead to improved customer satisfaction and successful product presentation. The right stock blister packaging can set your products apart on the shelves, making it crucial to choose wisely to maximize both functionality and aesthetic appeal.

Understanding the Importance of Stock Blister Packaging for Product Protection

When it comes to product protection, stock blister packaging plays a crucial role in ensuring that items remain safe during transportation and storage.

The clear plastic barrier not only safeguards products from physical damage such as shocks and drops but also protects them from environmental factors like moisture and dust. This type of packaging is particularly important for sensitive goods, including electronics and pharmaceuticals, where even the slightest compromise can lead to malfunction or contamination.

In addition to offering physical protection, stock blister packaging enhances product visibility, allowing consumers to see the item before purchase. This transparency can be a decisive factor in consumer decision-making, as it builds trust and satisfaction. Moreover, stock blister packages can be customized for different products, providing an effective balance between visibility and security. By selecting the appropriate design and material for blister packaging, businesses can significantly improve their product integrity while also appealing to a broader audience.

Key Factors to Consider When Choosing Stock Blister Packaging

When selecting the right stock blister packaging for your products, several key factors must be taken into account to ensure that it meets both functional and market requirements. The material used in blister packaging plays a critical role in determining product protection, shelf life, and regulatory compliance, especially in sectors like pharmaceuticals and healthcare. For instance, aluminum has emerged as a leading material in the healthcare blister packaging market, holding a substantial share due to its superior barrier properties against moisture and light.

Another important factor to consider is the design and configuration of the blister pack itself. Customization can enhance the user experience and ease of access, which is particularly vital for consumer-oriented products. Additionally, companies should evaluate the environmental impact of their packaging choices, as sustainability continues to be a significant concern in the industry. With the pharmaceutical packaging market projected to experience steady growth, making informed decisions about blister packaging will not only help in compliance but also in boosting brand reputation and consumer trust.

Factors Affecting the Choice of Stock Blister Packaging

Comparing Different Materials for Stock Blister Packaging Solutions

When selecting stock blister packaging for your products, it is essential to compare the different materials available. Each material offers unique benefits that can influence both the protection of your product and the overall consumer experience. Common materials used in blister packaging include plastic, paper, paperboard, glass, and metal. Among these, plastic is often favored for its versatility, lightweight properties, and cost-effectiveness, making it ideal for various applications, particularly in the pharmaceutical sector.

Paper and paperboard are also gaining traction, especially for environmentally conscious brands. These materials can provide sufficient protection while reducing the ecological footprint of packaging. Glass and metal, while not as common for blisters, offer superior barrier properties and can be ideal for specific products requiring enhanced containment. By understanding the characteristics of each material, brands can make informed decisions that align with their product requirements, sustainability goals, and consumer preferences, ultimately leading to improved market performance.

Design Tips for Customizing Your Stock Blister Packaging Effectively

When customizing stock blister packaging, understanding the design elements that resonate with your target audience is crucial. In recent years, consumer preferences have shifted towards visually appealing and eco-friendly packaging. According to a survey conducted by Packaging Strategies, over 60% of consumers prefer products with sustainable packaging. This trend emphasizes the need for companies to incorporate environmentally responsible materials and designs that not only catch the eye but also align with consumers' values.

Effective design tips include considering transparency and featuring a clean layout that highlights your product. Research by the Flexible Packaging Association suggests that 53% of consumers are influenced by packaging when making a purchase decision. Therefore, using bright colors and bold graphics can help products stand out on crowded shelves. Additionally, incorporating user-friendly features, such as easy-open tabs or resealable options, can enhance customer experience and encourage repeat purchases. By strategically implementing these design elements, brands can maximize the impact of their stock blister packaging and foster stronger connections with their customers.

Cost Analysis: Budgeting for Stock Blister Packaging Options

When considering the various stock blister packaging options available, a thorough cost analysis is crucial for effective budgeting. Start by evaluating the different types of materials such as PVC, PET, and PETG. Each material varies not only in durability and protective qualities but also in cost. Understanding the specific needs of your products can help you choose a material that fits both your budget and performance requirements. For example, if your items require higher protection, opting for a more robust material may be worthwhile despite a higher initial cost.

Next, factor in additional expenses such as tooling, printing, and shipping. While stock options might seem economical upfront, hidden costs can significantly impact your overall budget. Consider the trade-offs between custom designs and pre-made solutions, as custom tooling can lead to longer lead times and higher costs. Pricing strategies should include an analysis of long-term savings from using stock packaging that meets regulatory and safety standards, which could prevent undesirable logistics costs down the line. By looking at both immediate and future expenses, you can make informed decisions that align with your financial capabilities while ensuring your product remains protected and presentable.

How to Choose the Right Stock Blister Packaging for Your Products - Cost Analysis: Budgeting for Stock Blister Packaging Options

| Packaging Material | Cost per Unit | Durability Rating | Sustainability Index | Lead Time (Days) |

|---|---|---|---|---|

| PET (Polyethylene Terephthalate) | $0.15 | High | 70% | 10 |

| PVC (Polyvinyl Chloride) | $0.20 | Medium | 40% | 12 |

| PLA (Polylactic Acid) | $0.25 | Medium | 90% | 15 |

| PP (Polypropylene) | $0.18 | High | 60% | 8 |

| Aluminum Blister | $0.30 | Very High | 50% | 20 |

Related Posts

-

5 Essential Tips for Choosing the Best Blister Packaging Materials

-

7 Best Strategies to Optimize Your Blister Machine Investment

-

Ultimate Guide to Mastering Clam Packaging for Global Buyers

-

Addressing Challenges in Clam Packaging for Optimal Product Preservation

-

Ultimate Checklist for Optimizing Your Thermoforming Plastic Production Process

-

How to Optimize Your Blister Card Packaging for Enhanced Product Visibility and Sales Performance