Understanding the Growth and Efficiency of Blister Card Packaging Machines in the Modern Packaging Industry

In the rapidly evolving landscape of the modern packaging industry, the blister card packaging machine stands out as a pivotal technology driving both growth and efficiency. This machinery plays a crucial role in the packaging process, offering enhanced protection for products while ensuring visibility and convenience for consumers. As demand for packaged goods rises, manufacturers are increasingly turning to blister card packaging machines to streamline operations and reduce costs. The versatility and adaptability of these machines make them suitable for an array of industries, from pharmaceuticals to consumer electronics.

Understanding the factors contributing to the expansion and effectiveness of blister card packaging machines is essential for businesses aiming to remain competitive in this dynamic market. This article delves into the innovative features and operational efficiencies of these machines, highlighting their significance in meeting the contemporary challenges of packaging solutions.

Benefits of Blister Card Packaging in the Modern Industry

Blister card packaging has gained immense popularity in the modern industry due to its numerous benefits that appeal to manufacturers and consumers alike. One of the primary advantages of this packaging type is its ability to provide enhanced product visibility. The clear plastic blister casing allows potential customers to see the product directly, which helps in attracting attention and encouraging purchases. Additionally, the printed card backing can be customized with vibrant graphics and information, further enhancing brand recognition and marketing efforts.

Blister card packaging has gained immense popularity in the modern industry due to its numerous benefits that appeal to manufacturers and consumers alike. One of the primary advantages of this packaging type is its ability to provide enhanced product visibility. The clear plastic blister casing allows potential customers to see the product directly, which helps in attracting attention and encouraging purchases. Additionally, the printed card backing can be customized with vibrant graphics and information, further enhancing brand recognition and marketing efforts.

Another significant benefit of blister card packaging is its robust protection of the products inside. The packaging is designed to securely hold items in place, reducing the risk of damage during transportation and storage. This form of packaging is especially beneficial for fragile items, such as pharmaceuticals or small electronics, where safety and integrity are paramount. Furthermore, blister cards facilitate tamper-evident packaging, thus ensuring product security and consumer trust. With its combination of aesthetic appeal, protective qualities, and practicality, blister card packaging continues to be a preferred choice in various sectors of the modern industry.

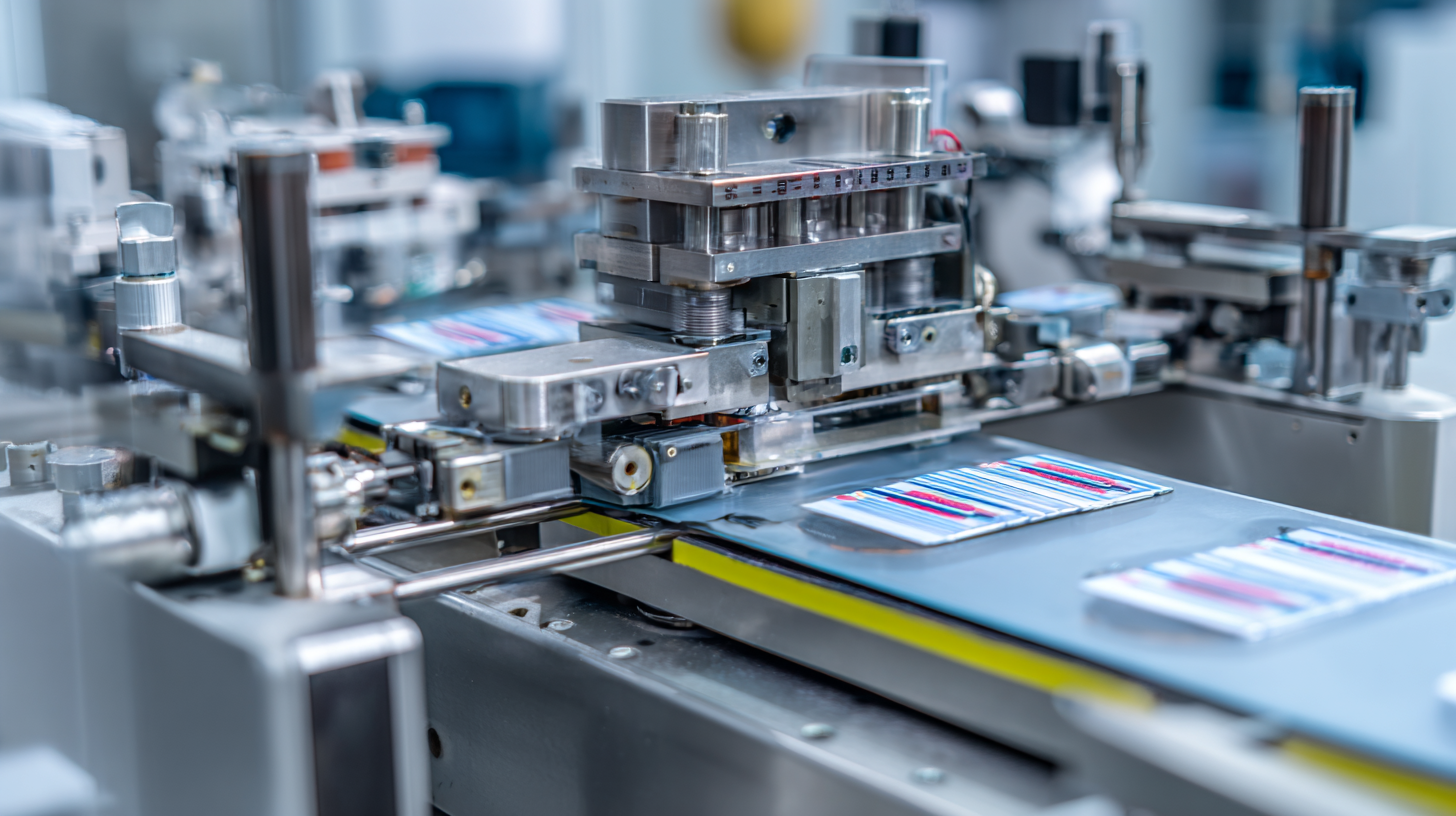

Key Features of High-Efficiency Blister Card Packaging Machines

Blister card packaging machines have become increasingly prominent in the modern packaging industry due to their high efficiency and adaptability. A report from Smithers Pira indicates that the global blister packaging market is expected to grow at a CAGR of 6.5% from 2021 to 2026, driven by expanding pharmaceutical and consumer goods sectors. High-efficiency blister card packaging machines are pivotal in meeting this demand, providing faster throughput and superior cost-effectiveness.

Blister card packaging machines have become increasingly prominent in the modern packaging industry due to their high efficiency and adaptability. A report from Smithers Pira indicates that the global blister packaging market is expected to grow at a CAGR of 6.5% from 2021 to 2026, driven by expanding pharmaceutical and consumer goods sectors. High-efficiency blister card packaging machines are pivotal in meeting this demand, providing faster throughput and superior cost-effectiveness.

Key features of these machines include advanced automation capabilities, which streamline the packaging process and minimize manual intervention. Many high-efficiency models are equipped with servo-driven systems that enhance precision and speed, achieving production rates exceeding 300 cycles per minute. Data from the Association for Packaging and Processing Technologies highlights that such automation can lead to a reduction in operational costs by up to 30%. Additionally, these machines often feature customizable tooling and easy changeover processes, allowing manufacturers to respond swiftly to market trends without significant downtime.

Factors Influencing the Growth of Blister Card Packaging Demand

The demand for blister card packaging has surged in recent years due to several key factors. One significant driver is the increasing need for secure and tamper-proof packaging solutions in various sectors, including pharmaceuticals, consumer goods, and electronics. As companies strive to enhance product safety and maintain brand integrity, blister packaging offers a clear advantage with its ability to protect products from contamination while providing visible proof of tampering.

Another influencing factor is the growing consumer preference for convenience and ease of use. Blister card packaging facilitates simple access to products, making it an attractive option for customers. This trend is particularly evident in the pharmaceutical industry, where patients seek user-friendly packaging that allows for easy dosage and minimizes the risk of exposure. Additionally, the rise of e-commerce has led to increased shipping demands for durable and lightweight packaging solutions, further boosting the blister card packaging segment. As businesses adapt to these evolving consumer needs, the growth trajectory for blister card packaging machines is expected to remain strong.

Best Practices for Optimizing Blister Card Packaging Processes

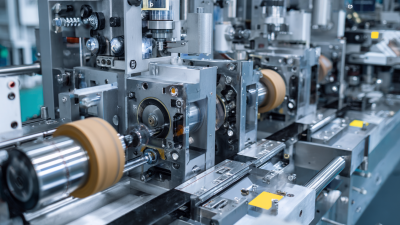

Blister card packaging has become a pivotal solution in the modern packaging industry, boasting a market growth rate of approximately 4.5% annually, according to a recent industry analysis. To optimize blister card packaging processes, the implementation of best practices is essential. This includes investing in high-quality materials that enhance product visibility while ensuring durability. For example, using PVC or PET for blister cards can improve both the aesthetic appeal and structural integrity, reducing the likelihood of product damage during transit.

Moreover, automation plays a critical role in enhancing efficiency. Incorporating state-of-the-art blister card packaging machines can accelerate production rates significantly, with reports indicating up to a 30% increase in output when compared to traditional methods. Additionally, regular maintenance and calibration of these machines can minimize downtime and improve operational reliability.

Industry experts suggest that maintaining an optimal temperature control during the packaging process not only ensures better adhesion but also contributes to overall product shelf life, affirming the need for continuous innovation in packaging technology.

Future Trends in Blister Card Packaging Technology and Innovation

As the modern packaging industry evolves, blister card packaging technology is poised for significant innovations. One of the key trends is the integration of smart technology into packaging solutions. This allows for the incorporation of features such as QR codes, which enable consumers to access detailed product information, enhancing the user experience. Automated production lines are also becoming more prevalent, improving efficiency and reducing production times.

Tips: When considering new blister card packaging technology, focus on sustainability by utilizing eco-friendly materials. Also, explore options for customization to better meet the specific needs of your products and target audience.

In addition, advancements in materials science are leading to thinner, yet sturdier, blister cards that offer better protection while reducing waste. The shift towards digital printing allows brands to adapt quickly to changing designs and promotional needs, enhancing market responsiveness. Embracing these innovations will be crucial for companies looking to stay competitive in the fast-paced packaging landscape.

Tips: To keep up with trends, regularly assess your packaging processes for potential upgrades and invest in training your team on new technologies for seamless implementation.

Related Posts

-

Understanding the Role of Blister Packaging Machines in Modern Manufacturing Processes

-

Exploring Innovative Alternatives to the Traditional Blister Packing Machine

-

What is the Importance of Blister Packaging Machine in Modern Manufacturing

-

7 Best Strategies to Optimize Your Blister Machine Investment

-

How to Achieve Optimal Results with Blister Card Printing in Modern Packaging Design

-

Exploring the Benefits of Using an Automatic Blister Packing Machine in Modern Manufacturing