What is the Importance of Blister Packaging Machine in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the blister packaging machine has emerged as a crucial player in enhancing product protection and efficiency. According to a report by MarketsandMarkets, the blister packaging market is projected to reach approximately $32.39 billion by 2025, with a significant compound annual growth rate (CAGR) of 5.8% from 2020 to 2025. This growth underscores the increasing reliance on blister packaging solutions across various sectors, including pharmaceuticals, consumer goods, and food industries. The incorporation of blister packaging machines not only streamlines the packaging process but also ensures compliance with stringent regulatory standards, reduces material waste, and improves shelf life for products.

As manufacturers continue to seek innovative packaging solutions that cater to consumer safety and sustainability, understanding the vital role of blister packaging machines becomes essential for staying competitive in today's market.

The Evolution of Blister Packaging Machines in Manufacturing Processes

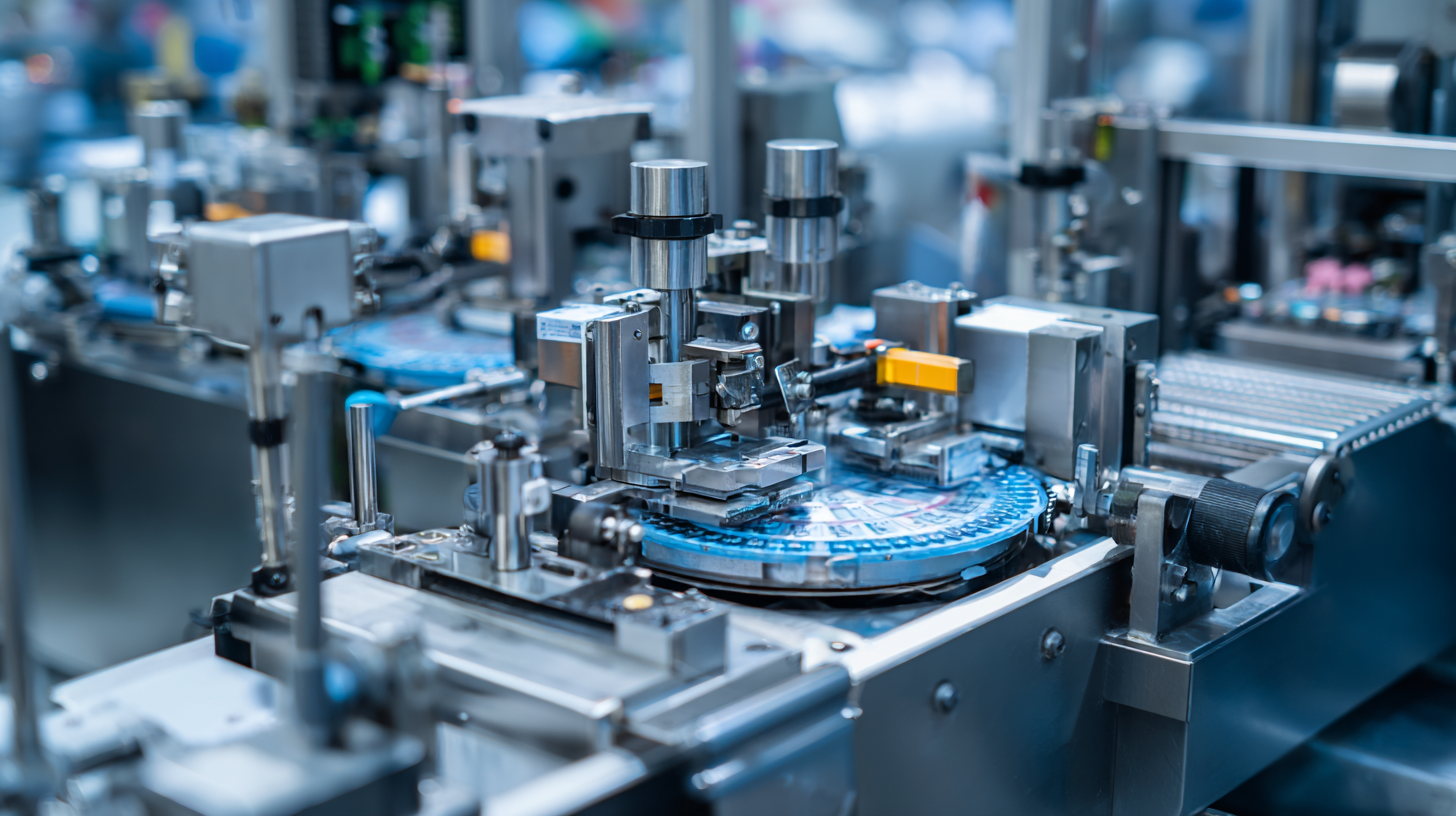

The evolution of blister packaging machines has been a significant driving force in modern manufacturing processes, reflecting advancements in technology and growing industry demands. Traditionally, blister packaging was a manual process, often prone to errors and inefficiencies. However, with the advent of automated machinery, this process has undergone substantial transformation. Today’s machines incorporate sophisticated technology such as machine vision and AI, enhancing the quality control aspect of packaging. These innovations not only improve accuracy but also increase production speed, allowing manufacturers to meet market demands rapidly.

Furthermore, recent trends indicate a shift toward eco-friendly and sustainable packaging solutions. As regulatory pressures and consumer preferences evolve, blister packaging machines are adapting to include features that support these goals.

For instance, the introduction of machines designed for quick setup and flexibility allows manufacturers to respond more dynamically to the changing landscape of product packaging. Such advancements signal a promising future for blister packaging, ensuring it remains a vital component of manufacturing processes in the pharmaceutical sector and beyond, while also aligning with the industry's sustainability objectives.

Key Benefits of Using Blister Packaging in Modern Industries

Blister packaging has emerged as a crucial component in modern manufacturing, offering several key benefits that enhance product protection and consumer appeal. One of the primary advantages is its ability to safeguard items from environmental factors such as moisture, dust, and tampering. By creating an airtight seal, blister packaging ensures that products maintain their quality and integrity throughout their shelf life. This is particularly vital for pharmaceuticals, electronics, and food products, where contamination or degradation can have serious consequences.

Furthermore, blister packaging is highly customizable, allowing manufacturers to design packaging that not only fits the product perfectly but also aligns with branding strategies. The transparent nature of blister packs gives consumers a clear view of the product, which can help facilitate informed purchasing decisions. Additionally, advancements in blister packaging machines have streamlined production processes, increasing efficiency and reducing material waste. As industries continue to prioritize sustainability and consumer safety, the importance of blister packaging in modern manufacturing cannot be overstated.

Choosing the Right Blister Packaging Machine for Your Production Needs

Choosing the right blister packaging machine is crucial for manufacturers aiming to meet the specific demands of modern production. With the increasing complexity of consumer expectations, particularly in the pharmaceutical and dietary supplement sectors, selecting equipment that can adapt to various specifications is a key consideration. As the need for efficient and safe packaging grows, manufacturers must prioritize machines that integrate advanced technologies, such as vision systems, which enhance quality control by monitoring blister packs through sophisticated image analysis.

Moreover, the trend towards sustainable and recyclable materials has intensified the need for innovative blister packaging solutions. When selecting a blister packaging machine, manufacturers should evaluate options that can process thinner alternative materials, as these require specialized design and engineering capabilities. The intersection of automation and sustainable practices not only meets regulatory pressures but also aligns with consumer demand for environmentally friendly products. By investing in the right blister packaging machinery, companies can improve their production efficiency while keeping pace with evolving market trends.

The Importance of Blister Packaging Machine in Modern Manufacturing

This chart illustrates the various factors influencing the selection of blister packaging machines in modern manufacturing. The data reflects the percentage importance of each factor based on industry surveys.

Innovative Features of Today's Blister Packaging Technologies

In today's fast-paced manufacturing landscape,

blister packaging machines have evolved significantly, incorporating innovative features that enhance efficiency and product protection. Modern blister packaging technologies are designed to meet the demands of diverse industries, from pharmaceuticals to consumer goods. One of the standout advancements is the integration of automation and smart technology, enabling high-speed production with minimal human intervention. This automation not only accelerates the packaging process but also ensures consistency and precision, reducing the risk of errors.

Another remarkable feature of today's blister packaging machines is the incorporation of sustainable materials and eco-friendly practices. As consumers become increasingly environmentally conscious, manufacturers are responding by adopting recyclable and biodegradable materials for packaging. These innovations not only reduce waste but also promote a brand's commitment to sustainability, which is vital in the current market. Additionally, the versatility of modern machines allows for customization in design, accommodating various product shapes and sizes while ensuring optimal shelf life and protection. This flexibility is crucial for businesses aiming to differentiate themselves in a competitive landscape.

Best Practices for Maintaining and Optimizing Blister Packaging Machines

Blister packaging machines play a vital role in modern manufacturing, particularly in the pharmaceutical, food, and consumer goods industries. To ensure these machines operate at peak efficiency, it is essential to adopt best practices for their maintenance and optimization. Regularly scheduled maintenance checks can significantly reduce the likelihood of unexpected downtimes and extend the lifespan of the equipment. It is advisable to inspect key components such as seals, films, and heat sources to ensure they are functioning correctly. Additionally, keeping the machines clean and free from debris will enhance their performance and maintain product integrity.

Optimizing blister packaging processes involves not only routine maintenance but also continuous training for operators. Ensuring that operators are well-versed in the latest technology and techniques can help them identify issues early and implement preventative measures. Utilizing data analytics to monitor machine performance can help pinpoint inefficiencies and allow for quick adjustments. Incorporating automated systems can also elevate the packaging process, increasing speed and reducing human error, ultimately leading to a more reliable production output. By focusing on these best practices, manufacturers can maximize their investment in blister packaging technology while ensuring high-quality output.

Related Posts

-

Exploring Innovative Alternatives to the Traditional Blister Packing Machine

-

5 Essential Tips for Choosing the Best Blister Packaging Materials

-

Essential Checklist for Choosing the Right Plastic Clamshells for Your Products

-

How to Optimize Your Blister Card Packaging for Enhanced Product Visibility and Sales Performance

-

Ultimate Checklist for Optimizing Your Thermoforming Plastic Production Process

-

Essential Guide to Choosing the Right Stock Clamshell Packaging for Global Markets