How to Achieve Optimal Results with Blister Card Printing in Modern Packaging Design

In the competitive landscape of modern packaging design, achieving optimal results with blister card printing is crucial for product differentiation and consumer appeal. According to a recent study by Smithers Pira, the global market for flexible packaging is projected to reach $300 billion by 2023, highlighting the rising demand for innovative packaging solutions like blister cards. This method not only enhances product visibility but also provides adequate protection, making it a preferred choice in sectors like pharmaceuticals and consumer goods. Moreover, a report from MarketsandMarkets indicates that the blister packaging market alone is expected to grow at a CAGR of 5.5%, underscoring the importance of leveraging blister card printing techniques to meet evolving consumer expectations. The effectiveness of blister cards lies in their ability to combine functionality with aesthetic appeal, which is essential for capturing consumer interest in today’s fast-paced retail environment.

Understanding the Fundamentals of Blister Card Printing in Packaging Design

Blister card printing is a pivotal aspect of modern packaging design, combining functionality with visual appeal. Understanding the fundamentals of this process is essential for brands aiming to maximize shelf impact and consumer engagement. According to a recent report by Smithers Pira, the global market for blister packaging is expected to reach $19.9 billion by 2024, driven by the growing demand in sectors like pharmaceuticals, cosmetics, and consumer electronics. This trend highlights the necessity for innovative blister card designs that not only protect products but also attract buyers’ attention.

From an operational perspective, successful blister card printing hinges on selecting the right materials and printing techniques. High-quality PET (Polyethylene Terephthalate) and PVC (Polyvinyl Chloride) are commonly used due to their excellent durability and transparency, allowing consumers to view the product within. A study by Allied Market Research found that 51% of consumers consider packaging to be influential in their purchasing decisions, underlining the importance of investing in aesthetic aspects alongside functionality. Utilizing advanced printing technologies, such as digital and offset printing, can enhance design precision and reduce lead times, making it easier for brands to adapt to market trends swiftly.

Choosing the Right Materials for High-Quality Blister Card Printing

When it comes to blister card printing, selecting the right materials is crucial for achieving high-quality results. The base material, typically made from PVC, PET, or paperboard, plays a vital role in both the aesthetics and functionality of the packaging. PVC is known for its versatility and excellent clarity, making it ideal for products that need to showcase their features. However, PET is favored for being more environmentally friendly, offering high durability and resistance to impact, which is essential for protecting the product inside.

In addition to the substrate, the choice of printing inks is equally important. Water-based inks are a popular choice because they are less harmful to the environment and produce vibrant colors with excellent adhesion. Furthermore, ensuring compatibility between the inks and the chosen substrate can enhance the overall quality of the print. By carefully selecting these materials, manufacturers can not only improve the appearance of the blister card but also boost its performance in protecting the product, ultimately leading to a more effective and attractive packaging solution in the market.

Design Techniques for Eye-Catching and Functional Blister Cards

Blister card printing has emerged as a vital aspect of modern packaging design, effectively marrying aesthetics with functionality. To create eye-catching blister cards, designers should focus on several key techniques. First, utilizing bold colors and unique textures can capture consumer attention and enhance product visibility. This approach not only attracts potential buyers but also communicates the product's value. The right combination of design elements, such as graphics and typography, plays a crucial role in establishing a strong brand identity.

Additionally, functionality cannot be overlooked in blister card design. Incorporating easy-to-open features and clear product information improves the user experience, encouraging sales. Designers should consider the best materials for durability while maintaining sustainability, mirroring the increasing consumer demand for eco-friendly packaging solutions. By striking the right balance between aesthetic appeal and practical usability, blister cards can significantly enhance product placement and consumer satisfaction in a competitive market.

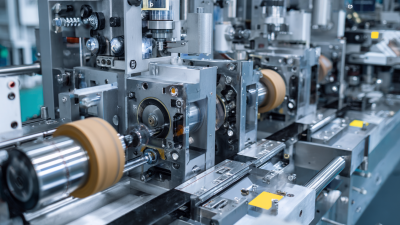

Optimizing Production Processes for Efficient Blister Card Manufacturing

In modern packaging design, the focus on optimizing production processes is essential for efficient blister card manufacturing. The integration of advanced technologies and streamlined workflows can significantly enhance the quality and speed of production. For instance, adopting automated machinery not only reduces labor costs but also minimizes errors, ensuring that each blister card meets the required specifications. This is particularly important in industries where precision is paramount.

Additionally, the sourcing of sustainable materials, such as polylactic acid (PLA), plays a crucial role in enhancing the environmental credentials of blister card packaging. PLA, a biodegradable plastic made from renewable resources, aligns with the growing trend towards eco-friendly packaging solutions. By utilizing such materials, manufacturers can create products that not only meet consumer demands for sustainability but also comply with regulations aimed at reducing plastic waste. Emphasizing sustainable practices in the manufacturing process not only improves efficiency but also strengthens brand reputation in a competitive marketplace.

Ensuring Sustainability in Blister Card Packaging Solutions

Sustainability in blister card packaging is increasingly vital in today’s environmentally conscious market. To minimize environmental impact, companies are turning to eco-friendly materials and innovative designs that reduce waste. Utilizing recyclable plastics and biodegradable alternatives can significantly lower the carbon footprint of blister packaging. Additionally, optimizing the design to use less material while still maintaining functionality ensures that packaging meets environmental standards without compromising product integrity.

Moreover, adopting efficient production processes can further enhance sustainability. Implementing technologies that reduce energy consumption and waste during manufacturing not only supports sustainability goals but also lowers costs in the long run. Collaborating with suppliers committed to sustainable practices can foster a more transparent supply chain and promote a circular economy. By prioritizing sustainability in blister card packaging solutions, brands can appeal to eco-conscious consumers while contributing positively to the planet.

Related Posts

-

5 Essential Tips for Choosing the Best Blister Packaging Materials

-

How to Optimize Your Blister Card Packaging for Enhanced Product Visibility and Sales Performance

-

How to Select the Right Blister Card Packaging for Your Product

-

Essential Checklist for Choosing the Right Plastic Clamshells for Your Products

-

7 Best Strategies to Optimize Your Blister Machine Investment

-

How to Choose the Right Stock Blister Packaging for Your Products