How to Select the Right Blister Card Packaging for Your Product

When it comes to product presentation and protection, selecting the right blister card packaging is essential for ensuring that your items stand out on the retail shelf while remaining safe from damage. Blister card packaging is commonly used for a variety of products, ranging from cosmetics to electronics, providing an attractive visual appeal and convenience for consumers.

When it comes to product presentation and protection, selecting the right blister card packaging is essential for ensuring that your items stand out on the retail shelf while remaining safe from damage. Blister card packaging is commonly used for a variety of products, ranging from cosmetics to electronics, providing an attractive visual appeal and convenience for consumers.

However, with numerous factors to consider—including product dimensions, materials, and branding strategies—it can be overwhelming to choose the most suitable blister card packaging for your specific needs. This guide will walk you through key considerations and best practices to help you make informed decisions that enhance the functionality and aesthetic of your product packaging, ultimately contributing to a more successful market presence.

Understanding Different Types of Blister Card Packaging and Their Uses

Blister card packaging comes in various forms, each catering to specific product needs and market demands. The most common types include standard blisters, clamshells, and slide blisters. Standard blisters generally consist of a pre-formed plastic cavity that holds the product securely, making them ideal for small items like pills or electronics. This type of packaging is cost-effective and offers visibility and protection, which boosts consumer appeal.

Clamshell packaging, characterized by its hinged design, provides enhanced security and tamper resistance, making it a popular choice for high-value items such as tools and consumer electronics. The transparency of clamshells allows customers to see the product while ensuring it is well-protected from damage. Meanwhile, slide blisters, which feature a sliding card that holds the product in place, are particularly convenient for products requiring easy access, such as kitchen gadgets. Each blister card type has tailored benefits, making it crucial to understand these distinctions when selecting the right packaging for your product.

Evaluating Material Options: Choosing Between PET, PVC, and PS

When selecting blister card packaging for a product, the choice of material is crucial for both functionality and environmental impact. Among the most common options—PET (Polyethylene Terephthalate), PVC (Polyvinyl Chloride), and PS (Polystyrene)—each material presents distinct advantages and challenges. Recent advancements in polymer technologies highlight the potential of PET as a more sustainable choice, given its recyclability and lower environmental footprint when compared to PVC and PS. Research into the chemical recycling processes for PET has shown promising results, which could improve its lifecycle management and reduce waste.

On the other hand, the environmental issues surrounding plastic materials are becoming increasingly pressing. Studies indicate that microplastics leach from various plastics, influencing both human health and ecological systems. As consumers and manufacturers become more conscious of these challenges, opting for materials with proven recycling efficiency, like PET, can contribute to a more sustainable approach in packaging. In addition, evaluating the potential impact of materials on product safety, alongside their environmental implications, is essential in ensuring that blister card packaging aligns with both performance and eco-friendly standards.

Assessing Design Elements: Optimal Card Size and Shape for Your Product

When selecting the right blister card packaging for your product, one of the critical design elements to consider is the size and shape of the card. Research from Packaging Strategies indicates that nearly 70% of consumers make a purchase decision based primarily on the packaging. Therefore, the card size must not only accommodate the product but also enhance visibility and appeal on retail shelves. A well-optimized blister card should allow potential customers to see the product clearly while providing essential information, such as branding and usage instructions.

In terms of shape, a custom design can significantly impact the product's shelf presence. According to a report by Freedonia Group, unique shapes can increase a product's marketability by approximately 30% as they attract attention in a crowded market. For example, a standard rectangular shape may be appropriate for items like tools or electronics, whereas a more ergonomic or themed shape could be more effective for toys or cosmetics. By carefully assessing these design elements, brands can create blister card packaging that not only houses their product securely but also serves as an effective marketing tool.

How to Select the Right Blister Card Packaging for Your Product - Assessing Design Elements: Optimal Card Size and Shape for Your Product

| Product Type | Optimal Card Size (inches) | Optimal Card Shape | Recommended Material | Key Features |

|---|---|---|---|---|

| Pharmaceuticals | 4 x 6 | Rectangular | Plastic PET | Child-proof, Tamper-evident |

| Electronics | 5 x 7 | Square | Blister card with PVC | Clear visibility, Durable |

| Cosmetics | 6 x 4 | Rectangular | Plastic PET or PP | Attractive design, Recyclable |

| Tools & Hardware | 8 x 10 | Rectangular | Thick cardboard with plastic | Heavy-duty, Easy to hang |

| Toys | 7 x 9 | Custom shapes | Biodegradable cardboard | Visually appealing, Fun designs |

Analyzing Cost vs. Benefit: Budgeting for Blister Card Packaging Solutions

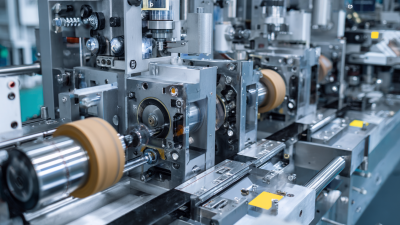

When considering blister card packaging for your products, evaluating the cost versus benefits is critical. According to the recent "Blister Packaging Cost & Supplier Intelligence Report, 2030," the rise of blister packaging has been attributed to its smart design with functionalities such as child resistance and anti-counterfeiting measures. These attributes not only enhance consumer safety but also help brands reduce losses from counterfeit products, which can be a significant concern in various industries.

The setup cost of a packaging material manufacturing plant provides an essential backdrop for budgeting blister card solutions. Detailed reports on plant setup reveal that initial investments can vary based on layout, machinery needs, and overall operational requirements. By carefully analyzing these factors alongside the benefits offered by blister packaging, businesses can better allocate their budgets, ensuring that they choose the right packaging solution that aligns with their operational goals and consumer expectations. For manufacturers, understanding the balance between upfront costs and long-term benefits is crucial for sustainable growth in a competitive market.

Compliance and Safety: Navigating Regulatory Standards for Packaging Materials

When selecting blister card packaging, understanding compliance and safety regulations is paramount.

The packaging materials must adhere to specific regulatory standards that govern safety, especially for products that come in direct contact with consumers,

such as pharmaceuticals and food items. It's essential to familiarize yourself with regulations set by organizations like the

FDA or EU directives to ensure that the materials used are safe and suitable for the intended purpose.

Additionally, evaluating the sourcing and composition of packaging materials is critical. Manufacturers should provide documentation

regarding the material's safety, including information on potential contaminants and whether it meets the necessary standards for your market.

Consideration of material certifications and proper labeling can significantly enhance the credibility of your product and alleviate safety concerns

from consumers. By prioritizing compliance with regulatory standards, businesses not only protect their customers but also build trust

and reliability in their brand.

Related Posts

-

5 Essential Tips for Choosing the Best Blister Packaging Materials

-

How to Optimize Your Blister Card Packaging for Enhanced Product Visibility and Sales Performance

-

How to Choose the Right Stock Blister Packaging for Your Products

-

7 Best Strategies to Optimize Your Blister Machine Investment

-

Addressing Challenges in Clam Packaging for Optimal Product Preservation

-

How to Choose the Right Clear Clamshell Packaging for Your Products