How to Select the Right Blister Packing Machine for Your Production Needs

Selecting the right blister packing machine for your production needs is crucial in maintaining efficiency and product integrity, especially as the global blister packaging market is projected to reach $35 billion by 2026, growing at a CAGR of 6.7% from 2021 to 2026, according to a report by Mordor Intelligence. This increase is driven by the rising demand for pharmaceutical products and advanced packaging solutions that enhance product shelf life and reduce contamination risks.

Selecting the right blister packing machine for your production needs is crucial in maintaining efficiency and product integrity, especially as the global blister packaging market is projected to reach $35 billion by 2026, growing at a CAGR of 6.7% from 2021 to 2026, according to a report by Mordor Intelligence. This increase is driven by the rising demand for pharmaceutical products and advanced packaging solutions that enhance product shelf life and reduce contamination risks.

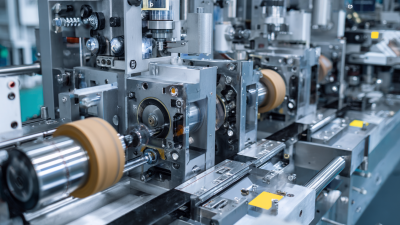

With numerous options available, it can be overwhelming to choose a machine that aligns with specific production requirements, such as speed, scale, and material compatibility. Understanding these factors is essential to ensure that the blister packing machine not only meets industry standards but also optimizes overall production efficiency and cost-effectiveness. As manufacturers face increasing pressure to ensure compliance and quality, making an informed decision becomes paramount.

Understanding Your Production Requirements for Blister Packing Machines

When selecting a blister packing machine, understanding your production requirements is paramount. Begin by assessing the volume of packaging you need on a daily basis. This includes estimating the number of units per hour and ensuring that the chosen machine can handle these rates without compromising quality. Additionally, consider the types of products you will be packing, such as tablets, capsules, or other items, as this will influence the machine's design and functionality.

Tips: Engage with your production team to gather insights about the expected workload and any potential fluctuations in demand. This will help you choose a machine that offers flexibility in speed and adaptability to various product sizes.

Another critical factor is the regulatory requirements specific to your industry. Pharmaceutical and medical packaging, for example, often have stringent compliance standards. Verify that the blister packing machine can meet these regulations, particularly when it comes to safety and material specifications.

Tips: Conduct thorough research into the certifications and standards relevant to your products, and consult manufacturers directly about their compliance capabilities to avoid issues later in the production process.

Evaluating Different Types of Blister Packing Machines Available

When selecting a blister packing machine, it is crucial to evaluate the various types available to ensure they meet your production needs. There are several types, including thermal forming, cold forming, and even semi-automatic and automatic machines. Thermal forming machines are popular for their efficiency and versatility, while cold forming machines are ideal for products requiring higher barrier properties. Semi-automatic machines may suit smaller production runs, while automatic machines can handle larger volumes with minimal human intervention.

Tips: Consider the specific materials you’ll be using for your blister packs. Different machines work best with certain types, such as PVC, PET, or aluminum, so aligning your material with the right technology is essential. Additionally, think about the machine's output capacity—assessing how many units you need to produce per hour can help narrow your options effectively.

It’s also important to evaluate the machine’s footprint and ease of integration into your current production line. A compact design can save valuable floor space, especially in facilities with limited room. Moreover, choosing a machine with user-friendly controls will streamline training for your staff and minimize downtime, enhancing overall productivity.

Key Features to Consider When Choosing a Blister Packing Machine

When selecting a blister packing machine, several key features should be considered to ensure it meets your production needs effectively. Firstly, the machine's speed is crucial. Depending on your manufacturing volume, you may require a high-speed machine capable of producing a large number of packs per minute. This ensures that your production line runs efficiently and meets demand without bottlenecks.

Another important aspect to evaluate is the machine's flexibility. A versatile blister packing machine can handle various product sizes and types, allowing you to adapt to changing production requirements. Additionally, consider the ease of operation and maintenance. Machines equipped with user-friendly controls and intuitive interfaces will reduce training time and minimize operational errors, leading to smoother workflows. Lastly, evaluate the machine's compatibility with your existing production line, ensuring it integrates seamlessly without requiring extensive modifications.

How to Select the Right Blister Packing Machine for Your Production Needs

| Feature | Description | Importance |

|---|---|---|

| Production Speed | The number of units produced per minute. | High |

| Machine Size | Dimensions of the machine, affecting installation space. | Medium |

| Ease of Use | User interface and control features for operation. | High |

| Material Compatibility | Types of materials the machine can handle. | High |

| Maintenance Requirements | Frequency and ease of machine upkeep. | Medium |

| Cost | Initial investment and operational costs. | High |

| Customization Options | Ability to customize machine features to specific needs. | Medium |

| Safety Features | Safety mechanisms to protect operators. | High |

Comparing Costs: Budgeting for Your Blister Packing Solution

When considering the acquisition of a blister packing machine, budgeting plays a crucial role in ensuring that you select a solution that meets both your production needs and financial constraints. First, it's important to evaluate not just the initial cost of the machine but also the long-term operational expenses. These may include maintenance, energy consumption, and the cost of consumables such as films and seals. A machine with a lower upfront price might seem attractive, but hidden operational costs can quickly escalate, affecting your bottom line.

Additionally, comparing costs across different machine models and manufacturers can provide insights into potential savings. While some machines may have higher initial costs, their efficiency and durability can lead to reduced downtime and lower maintenance needs. It's also advisable to consider the total cost of ownership (TCO), which accounts for the machine's lifespan and how it integrates with your existing production line. By carefully analyzing these costs, businesses can make informed decisions that align with their production goals while maintaining financial viability.

Cost Comparison of Blister Packing Machines

This chart compares the estimated costs of different types of blister packing machines based on their features and production capabilities. The data reflects common price ranges seen in the market.

Maintenance and Support: Ensuring Longevity of Your Packing Equipment

Regular maintenance is crucial for ensuring the longevity of your blister packing machine. A well-structured maintenance schedule that includes routine inspections, cleaning, and part replacements can significantly reduce downtime and enhance productivity. Operators should be trained to recognize signs of wear or malfunction, allowing for proactive intervention before serious issues arise. Implementing a preventive maintenance plan not only extends the lifespan of the equipment but also ensures consistent production quality.

Regular maintenance is crucial for ensuring the longevity of your blister packing machine. A well-structured maintenance schedule that includes routine inspections, cleaning, and part replacements can significantly reduce downtime and enhance productivity. Operators should be trained to recognize signs of wear or malfunction, allowing for proactive intervention before serious issues arise. Implementing a preventive maintenance plan not only extends the lifespan of the equipment but also ensures consistent production quality.

In addition to regular maintenance, having access to reliable support is essential for addressing unexpected challenges. Choosing a blister packing machine from a manufacturer that offers comprehensive support services can provide peace of mind. This includes access to technicians who are familiar with the specific machinery, as well as availability of spare parts. A strong support network can help facilitate quick repairs and seamless operations, thus minimizing disruption to production schedules. Overall, prioritizing maintenance and support lays the foundation for sustained performance and efficiency in your packing operations.

Related Posts

-

Exploring Innovative Alternatives to the Traditional Blister Packing Machine

-

What is the Importance of Blister Packaging Machine in Modern Manufacturing

-

7 Best Strategies to Optimize Your Blister Machine Investment

-

Essential Guide to Choosing the Right Stock Clamshell Packaging for Global Markets

-

5 Essential Tips for Choosing the Best Blister Packaging Materials

-

Essential Checklist for Choosing the Right Plastic Clamshells for Your Products