Why Thermoforming Plastic is the Future of Sustainable Packaging Solutions

As businesses and consumers increasingly prioritize sustainable practices, thermoforming plastic emerges as a groundbreaking solution in the realm of eco-friendly packaging. According to recent industry reports, the global market for sustainable packaging is projected to reach $654 billion by 2025, with a significant share attributed to innovation in materials such as thermoforming plastic. This versatile manufacturing process not only reduces waste through efficient use of materials but also enables companies to create lightweight, durable packages that can be easily recycled or repurposed. Additionally, thermoforming plastic can facilitate the use of biodegradable alternatives, further enhancing its status as a sustainable choice. With growing regulatory pressures and evolving consumer preferences, understanding how to effectively integrate thermoforming plastic into packaging strategies will be crucial for businesses aiming to lead the charge towards a more sustainable future.

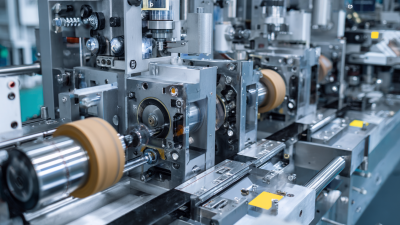

Understanding Thermoforming: The Process and Benefits for Sustainable Packaging

Thermoforming is emerging as a pivotal process in the realm of sustainable packaging solutions. This technique involves heating plastic sheets until malleable and then forming them into specific shapes using molds. The adaptability and efficiency of thermoforming make it particularly suitable for creating custom packaging that minimizes waste while optimizing material use. As brands increasingly prioritize eco-friendly practices, the demand for thermoformed packaging continues to grow, reflecting a broader industry shift towards sustainability.

The benefits of thermoforming extend beyond mere material consumption. This process allows for the integration of recycled materials, enhancing the circular economy within the packaging sector. Additionally, thermoformed products often weigh less than traditional packaging options, which can lead to reduced transportation costs and lower carbon emissions. Manufacturers are now focusing on innovative designs that not only protect products but also reduce their environmental footprint, making thermoforming a key player in the future of sustainable packaging.

Materials Matter: Exploring Eco-Friendly Plastics for Thermoforming

The shift toward sustainable packaging solutions has placed significant emphasis on materials used in thermoforming. Eco-friendly plastics, such as biodegradable polyesters and plant-based polyactic acid (PLA), are gaining traction within the industry. These materials offer excellent properties for thermoforming applications, including flexibility, strength, and clarity, which allow manufacturers to produce high-quality packaging without compromising on environmental responsibility. By choosing sustainable inputs, companies can significantly reduce their carbon footprint while meeting consumer demands for greener alternatives.

In addition to biodegradable options, recycling plays a crucial role in advancing eco-friendly thermoforming plastics. Recycled PET (rPET) is becoming a popular choice, as it maintains the functional properties of virgin plastic while utilizing materials that would otherwise contribute to landfill waste. This circular approach not only extends the life cycle of plastics but also aligns with broader environmental goals. As innovation in materials science continues, the range of eco-friendly plastics available for thermoforming is expected to expand, paving the way for more sustainable practices in the packaging industry.

Why Thermoforming Plastic is the Future of Sustainable Packaging Solutions

This chart illustrates the projected growth of eco-friendly plastics used in thermoforming over the next five years. The data shows a clear trend of increasing adoption due to environmental concerns and the demand for sustainable packaging solutions.

Design Innovations: How Thermoforming Enhances Customizable Packaging Solutions

Thermoforming has emerged as a game-changing technology in the realm of customizable packaging solutions, particularly within the context of sustainable practices. This innovative process allows for the efficient production of tailored packaging by heating plastic sheets until pliable and then shaping them according to specific product dimensions. This versatility not only accommodates various sizes and shapes but also minimizes material waste, hence aligning with eco-friendly objectives.

The market trends indicate a growing preference for thermoformed packaging, especially with the increasing demand for sustainable materials such as polycarbonate. Known for its durability and excellent optical clarity, polycarbonate serves as a lightweight alternative to glass, suitable for applications requiring resilience and thermal resistance. As industries shift towards more sustainable production methods, the adoption of thermoforming technology is set to play a pivotal role in enhancing packaging efficiency, improving product protection, and reducing environmental impact. Consequently, this trend reflects a larger movement within the packaging sector toward bespoke solutions that prioritize sustainability and consumer requirements.

Lifecycle Analysis: The Environmental Impact of Thermoformed Packaging

Thermoforming plastic has emerged as a frontrunner in sustainable packaging solutions, primarily due to its positive lifecycle analysis. This process involves heating plastic sheets to form intricate packages that are both lightweight and durable. One significant environmental benefit is the reduction of waste; thermoformed packaging can be designed to minimize excess material, helping to lower the overall carbon footprint associated with production and distribution.

Thermoforming plastic has emerged as a frontrunner in sustainable packaging solutions, primarily due to its positive lifecycle analysis. This process involves heating plastic sheets to form intricate packages that are both lightweight and durable. One significant environmental benefit is the reduction of waste; thermoformed packaging can be designed to minimize excess material, helping to lower the overall carbon footprint associated with production and distribution.

Tips for businesses considering thermoformed packaging include choosing materials that are recyclable and ensuring that the packaging design is efficient to avoid waste. Another important consideration is the reuse potential of thermoformed products; designs that encourage secondary usage can further enhance sustainability.

Moreover, the energy consumption during production is notably lower when compared to other packaging methods, such as injection molding. By opting for recyclable materials and emphasizing efficient production processes, companies can significantly diminish their environmental impact. Adopting thermoforming technology not only aligns with eco-friendly practices but also appeals to an increasingly environmentally conscious consumer base.

Real-World Applications: Successful Case Studies in Sustainable Thermoforming

Thermoforming plastic has emerged as a pivotal player in sustainable packaging, particularly highlighted by its successful applications in diverse industries. As traditional materials become increasingly scrutinized for their environmental impact, thermoformed solutions offer a notable alternative. Real-world examples demonstrate how companies are integrating these materials into their packaging strategies. For instance, in the pharmaceutical sector, recent evaluations of biodegradable packaging show a significant shift from conventional plastic to thermoformed options that reduce waste and enhance recyclability.

Case studies reveal that organizations adopting thermoforming techniques not only reduce their ecological footprint but also improve efficiency in their production processes. By utilizing renewable resources, these companies cater to a growing market of eco-conscious consumers, presenting a compelling case for the shift towards sustainable practices. The success of these initiatives underscores the versatility and promise of thermoforming plastics as a future-focused solution in sustainable packaging, showcasing the potential for broader adoption across various sectors.

Why Thermoforming Plastic is the Future of Sustainable Packaging Solutions - Real-World Applications: Successful Case Studies in Sustainable Thermoforming

| Application | Material Used | Features | Environmental Impact |

|---|---|---|---|

| Food Packaging | Recycled PET (rPET) | Lightweight, durable, and transparent. | Reduced plastic waste, lower carbon footprint. |

| Cosmetic Containers | Bioplastics | Customizable designs, smooth finish. | Biodegradable options reduce landfill waste. |

| Electronics Packaging | Polypropylene (PP) | Shock-resistant and insulating properties. | Extended product life, less environmental strain. |

| Retail Displays | Post-consumer recycled cardboard | Sustainable materials with versatile designs. | Encourages recycling, lowers deforestation rates. |

| Medical Instruments | Thermoformable biodegradable film | Sterile and safe for healthcare applications. | Reduces plastic pollution in medical waste. |

Related Posts

-

Ultimate Checklist for Optimizing Your Thermoforming Plastic Production Process

-

5 Essential Tips for Choosing the Best Blister Packaging Materials

-

Exploring Innovations in Automatic Tray Sealing Machines at the 138th Canton Fair 2025

-

Ultimate Guide to Mastering Clam Packaging for Global Buyers

-

How to Achieve Optimal Results with Blister Card Printing in Modern Packaging Design

-

7 Best Strategies to Optimize Your Blister Machine Investment